DTU applied in charging pile solution based on wireless monitoring technology

Time:2021-02-22 Source:Key words: Wireless DTU; Industrial DTU; Charging-pile; New energy; Internet +

1. Charging pile

Charging pile is a power plant of new energy-powered vehicles, which is similar to the tanker of gas station. Each charging pile is equipped with charging plug for kinds of electric vehicle’s charging, according to different voltage levels. Electric car charging pile uses AC, DC power supply. After brushing up the charge cards, charging pile will display charging capacity, charge time, expense and other data, and then print documents to achieve timing charging and metering charging.

2. Application Prospect

Since charging pile’s function is similar to tanker, this particularity purposes determine its constructions is characterized by multiple measured points, dispersion, wide coverage, long communication distance, and need to focus on management. With the rapid development of new energy vehicles, it request more flexibility and scalability network topology structure. Therefore, it need to consider the following issues when you choose the communication mode of electric car charging pile.

(1) The reliability of communication--the communication system need to withstand the harsh environment of long-term and strong electromagnetic interference or noise, and to maintain the smooth flow of communication.

(2) Construction costs--it need to consider the construction cost, long-term using and maintenance cost in meeting the reliability of premise.

(3) Bi-directional communication --it is not only to achieve the amount of information uploaded, but also to achieve a controlled amount of release.

(4) Multi-service data transfer rate--with the growing volume of terminal business in future, the communication between the master station and the sub-station or sub-station to the terminal communication, will have a high request on multi-service data transfer rates

(5) Communication flexibility and scalability--due to the characteristics of multi-surface control point, wide and dispersed surface, charging pile will use a standard communication protocol. With the growing business of electric power operation and “ALL IP” network technology’s development, IP-based services need to be considered bearer, and also require to facilitate the installation and construction, commissioning, operation and maintenance.

3. Communication mode

Electric car charging pile belongs to the distribution network side, their means of communication and distribution automation are often considered together. Communication is a key and difficult point of distribution automation. Different regions and conditions will lead to various communication application; specific to the electric car charging pile, its communication mode are wired and wireless:

(1) Wired communication

Wired communication: wired ethernet(RJ45 cable, optical fiber), industrial serial bus cable (RS485, RS232, CAN bus wire)

The main advantages of wired Ethernet are reliable data transmission, large network capacity; the disadvantages are wiring complexity, poor scalability and high construction costs, inflexible.

Industrial serial bus’s (RS485, RS232, CAN bus) advantages are reliable data transmission, simple design; the disadvantages are complex distribution network, poor scalability and high construction costs, inflexible, low traffic capacity.

(2) Wireless communication

Wireless communication is main using carrier's wireless network data to access services, such as: GPRS / CDMA / TD-SCDMA / WCDMA / EVDO and 4G LTE networks updated.

Advantages: low cost, short construction period, adaptable, scalable, and easy to maintain and easy expansion.

Therefore, a fixed IP or dynamic IP (available binding domain) and the port number which be provided from broadband cable networks according to 2G / 3G / 4G wireless data transmission technology, will be set on wireless terminal DTU to automatically resolve the domain name address, connect to the service side of the charging pile management platform, and then it can provide a variety of real-time data acquisition for the new energy and transportation industries, transmission, distribution, remote management and control, remote wireless data transmission.

4、System composition and networking

In the past three years, Xaimen Caimore has realized the gross volume applications of electric vehicle charging pile items on the NARI, XJ Electric, Shenzhen BYD, and other users, to achieve a self-charging technology based on embedded intelligent electric car pile end solutions and products. The overall system structure is shown as below:

This system is consisted of AC / DC charging pile, Caimore wireless data transmission terminal DTU, various 2G / 3G / 4G wireless networks and communications networks, charging pile systems management platform software and so on.

1, Caimore wireless data transmission DTU provides RS232 / RS485 / RS422/TTL interfaces for connection with charging pile. If the charge pile have a ethernet interface, you can choose Caimore’s another series wireless router for connection;

2, Wireless DTU through a variety of wireless networks to send the data of various charging pile for the server-side charging system management platform by transparent wireless way, system platform software including metering and billing system, charging monitoring system, power distribution monitoring system, security monitoring and control systems.

Charging pile terminal analysis chart

Electric car charging pile uses AC and DC power supply, without refueling, aerated, avoid to exhaust emissions & pollution of the environment, in line with China future urban development concept of the core elements of low-carbon.

5.System functions

The system can achieve the following functions:

1, real-time data transmission function: Through by 2G / 3G / 4G variety of wireless networks, DTU has a ability to transfer the real-time data of charge pile transparently (intact) to the server back-end’s charging pile systems management platform ;;

2, charging pile systems management platform software mainly realizes include metering and billing management system, charging monitoring system, power distribution monitoring system, security monitoring systems that several large pieces of application functionality;

3, remote monitoring capabilities: server management platform can monitor the operation of the charging pile, including uploading electricity transmitter, circuit breakers, industrial host, billing, touch screen, sensors and other equipment operating parameters, or through wireless DTU issued various work orders to the charging pile terminal equipment;

4, remote alarm maintenance functions: real-time monitoring of running status charging pile, once the fault alarm occurs, you can debug or upgrade remote maintenance, the timely processing of abnormal charging pile terminal problems;

5, application extensions: APP software that can access to third-party , using Caimore’s GPS positioning device and the corresponding system software, directly charging the phone APP user, you can achieve on a map addressing and navigation functions.

Charging pile system topology

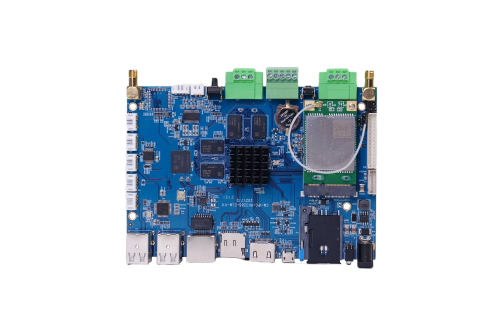

6. Caimore DTU wireless data transmission terminal presentation

DTU (Data Transfer Unit), full name is the data transfer unit, to provide users with high-speed, always online, TCP / UDP transparent data transmission of industrial wireless terminal devices. DTU uses high-speed high-performance industrial grade X86 architecture ARM9 embedded processor or high-performance embedded processor for real-time operating system software support platform, large memory, embedded TCP / IP protocol stack independent intellectual property rights, to provide users with high-speed , reliable, always-on data terminals, multiple protocol conversion, virtual private network system application.For user-network flow control, DTU product support voice, messaging, data and on-line trigger automatic disconnection timeout function. Also supports dual data center backup, and synchronize multiple data centers to receive data, and other functions.

6.1 Caimore DTU’s function advantages

1) Various interfaces: Provide RS232 or RS485 or TTL or RS422 or USB interface and support all kinds of interface;

2) Perfect network support: Provide GPRS/CDMA/WCDMA/TD-SCDMA/EVDO/LTE-FDD/

LTE-TDD to meet various clients request;

3) Three-tier system protection: based on the original two (software protection +WDT + CPU built-in protection) system protection, it adds stair system VWM (Virtual Man Watch) detection function to ensures that the stable & reliable system

4) Metal shell: using metal case to anti-radiation & anti-interference; shell and system security isolation, lightning protection design; meeting the power requirements of safety regulations; protection rating IP41; particularly suitable for harsh industrial control field;

5) Industrial grade design, support 5-32V power supply

6) All wireless modules are certified by the CGD or FCC certification or CE certification;

7) Industrial CPU with stable and reliable performance, Intelligent anti-dropped, online testing, online maintenance, automatically reset to ensure that equipment is always online;

8) Enlarge memory: FLASH 64Mbits, SDRAM, 256Mbits; a large enough memory to store programs and data;

9) Automatically obtain DNS: automatically acquire DNS and no longer need manual configuration to input DNS; avoid the serious DTU crash resulted from wrong choice of the abnormal DNS server;

10) Complete protocol stack: the new system loaded complete TCP / IP protocol stack, using comprehensive TCP / IP protocol stack, so that network traffic performance shows outstanding and the drop-line probability dramatically reduced;

11)EMC performance outstanding: passed 3000V electrical shock test, especially suitable for the condition of harsh industrial environments; system EMC / EMI performance excellent and system is stable and reliable; it has passed CE certification and EMC test;

12)Support SMS remote configuration, remote controlling, support SMS alarming;

13)Intelligent anti-dropped, online testing, online maintenance, automatically reset to ensure that equipment is always online;

14)Support remote WEB configuration, remote control, remote upgrade.

6.2 DTU series products qualification and testing

1, wireless communication online maintain patent technology

2, Moore Laboratory’s high and low temperature test report

3, Product Quality Inspection Detection of Fujian Institute

4, copyrights certificate

5, EMC test report

6, the state compulsory 3C certification

7.DTU "Innovation Award”

8.Shenzhen BYD user test reports