Intelligent remote management system of industrial robot manipulator

Time:2021-06-15 Source:1. Industry background

In the context of the rising tide of the global industrial Internet, modern industrial robot manipulators are used more and more widely in flexible processing and other production. The stability and reliability of industrial robots on the production line is of great significance to ensuring the economic benefits of enterprise production. In order to improve production efficiency and product yield, more and more manufacturing companies have begun to introduce high-efficiency, long-lasting and high-precision robotic manipulator applications. In the fields of automobiles, panels, wafers, metals, chemicals, plastics, food, etc., machinery Arms play an indispensable and key role in the factory. However, when a large number of robotic arms are introduced into the automated production process, sudden equipment failures have become a major hidden danger that affects production capacity, especially for high-tech manufacturers that require 24-hour non-stop production, any production line shutdown Both will cause huge losses. In order to ensure that the robotic arm can be maintained in time when it fails, some factories hire professional technicians with high salaries to stay in the factory. Often the utilization rate of this technician is very low, but the maintenance cost is high. How to remotely monitor the operating status of the robotic arm and forecast When a fault occurs, it is extremely important to accurately locate the fault.

The large-scale deployment of intelligent robot manipulators has complex structure and high maintenance costs. In addition to the high requirements for the professional maintenance ability of the technical personnel of the production enterprise, according to the current status of the manipulator application industry, the manipulator is also The high-quality service capabilities of manufacturing enterprises have put forward higher requirements. Nowadays, the Internet of Things technology and TCP/IP protocol transmit the status and alarm information of the industrial robot manipulator to the data monitoring center, realize its remote data monitoring and fault diagnosis, find the problem and quickly solve the fault, which is of great significance in modern industrial production .

2. System composition

The remote monitoring system of the industrial robot manipulator consists of three parts: the remote monitoring center, the data transmission terminal, and the terminal data collector.

The monitoring center includes WEB server, data server and VPN server, etc. The monitoring platform can continuously collect on-site real-time data 24 hours a day, dynamically display the changed data of each monitoring site on the site, automatically form reports and automatically send SMS alarms when abnormal data occurs. Field staff The monitoring platform can be accessed through the Internet to view the corresponding data in real time.

The data acquisition terminal includes a robotic arm controller, Ethernet PLC, and various sensors. Real-time collection of field PLC and sensor data through Ethernet, and real-time program control and program update to PLC and robotic arm controller.

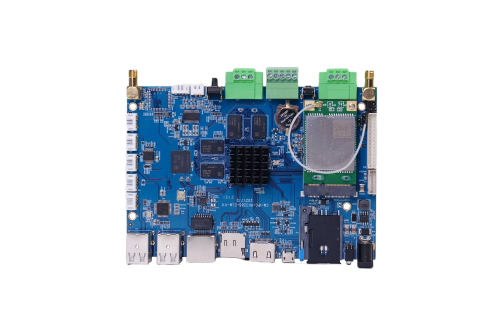

Data transmission terminal: In view of the requirements of various situations such as the interface of the collector and the working environment of the equipment, the industrial-grade wireless 5G/4G router of Caimore Communication is selected as the transmission equipment. The CM520 series industrial routers are a kind of wireless communication routers for the Internet of Things, which use the public 5G/4G full network to provide users with wireless long-distance data transmission functions. The product uses high-performance Qualcomm processor solutions and industrial-grade 5G/4G full Netcom network standard modules, embedded real-time operating system as the software support platform, and provides 4 Gigabit Ethernet (LAN) and 1 Ethernet port (WAN), 1 RS232, 1 RS485 and IO interface, can connect serial device, Ethernet device and WIFI connection device at the same time, realize data transparent transmission and routing function.

3. system topology

The monitoring center uses ADSL/optical fiber to access the Internet public network, obtains the public network IP, and builds a VPN server under the public network routing. As a VPN client, the Caimore Communication Router establishes a VPN tunnel through the local wired, WIFI or 5G/4G network and the server to realize the intranet interconnection between the two ends. The data collection system running on the database server can collect Ethernet PLC data connected to the Caimore router and control the robotic arm control program. So as to achieve real-time acquisition and monitoring of the operating status of the robotic arm.

4. System Function

1). Real-time collection and upload of operating data, with strong system scalability

Caimore Industrial 5G/4G routers are responsible for the important task of data transmission. The uplink adopts 5G/4G networking, which supports data transmission of various networks such as China Mobile, China Unicom, and telecommunications. The processing data is uploaded to the control center, and the equipment operation status can be viewed remotely. Industrial 5G/4G routers have high-speed data processing, large-capacity memory and storage space, built-in large-capacity memory and external expansion interface, support standard serial ports and Ethernet ports, can be expanded to connect to various lower computers, and the overall system scalability Strong.

2). Real-time analysis of production data, predictive maintenance of equipment, reducing equipment update costs. Industrial 5G/4G routers support a multi-language secondary development environment. Customers can customize data processing models and compare them with on-site real-time data and historical normal operating data. , Real-time analysis of production data, predict the possible problems of the equipment in advance, and achieve early maintenance and maintenance. Compared with the large amount of expense for new equipment due to the use of a large number of old equipment that cannot be repaired, this solution greatly reduces the cost of equipment update.

3). Cloud platform remote operation and maintenance, reducing operation and maintenance costs. Enterprises do not need to arrange professional and technical personnel to be permanently on-site to supervise. They can realize remote viewing and analysis of manipulator data in the monitoring background, and can perform equipment maintenance when the equipment is down, saving Utilize unprofitable robotic arm technicians to reduce operation and maintenance costs.

5.System Advantages

1. Stability

The industrial-grade high-performance processor can withstand the long-term harsh environment test to ensure the smoothness of communication; the reliable network connection and the device redial function can ensure that the device is always online.

2. Low cost

The wireless data transmission terminal is adopted, and the operator's 5G/4G network is used. There is no need for network wiring. The equipment is installed flexibly and is not affected by the geographical environment. Single-point equipment is cheap, reducing wiring problems and reducing costs.

3. Flexibility and scalability

Standard communication protocols and interfaces are used to facilitate installation, construction, commissioning, operation and maintenance. Multiple robotic arms in the workshop can be collected and controlled simultaneously.

4. Real-time

When the data is abnormal, the monitoring terminal can find out in time and issue instructions to control the robotic arm.

6.conclusion

Intelligent devices such as PLC and HMI in the industrial production site are connected to the CM520 industrial 5G/4G router through various industrial buses or high-speed Ethernet for data collection and remote transmission. After the completion, it is sent to the cloud system through the common transmission protocols of the Internet of Things such as MQTT and HTTP. The IoT cloud platform can be deployed in corporate private data centers or public cloud service platforms such as Azure, AWS, and Aliyun. The cloud platform can realize equipment remote status monitoring, real-time alarm notification and fault diagnosis analysis, remote fault location and program upgrade, equipment asset management, equipment preventive maintenance, and industrial big data mining functions.