Oilfield Intelligent Remote Monitoring System Solution

Time:2018-12-10 Source:1.Solution Design:

The system mainly uses the wireless RTU to integrate data acquisition, remote control and wireless communication to realize data collection and transmission. This series integrates analog signal acquisition, digital input, digital output, pulse counting, Ethernet communication, serial communication, RS485 communication and 4G/3G/2G wireless data communication. It can be directly connected. The analog signals, level signals, dry contacts, pulse signals, etc. outputted into various sensors, standard transmitter signals, meters, etc. are the best choice for implementing wireless measurement and control.

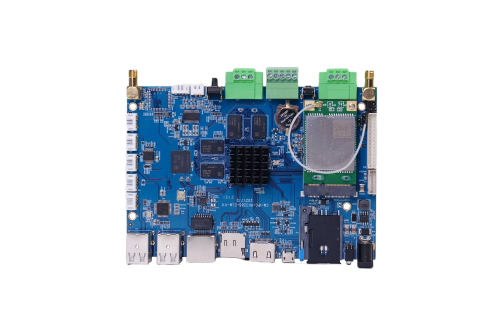

The core of the wireless RTU is the monitor, which is composed of a microprocessor, a micro power wireless transceiver module, a wireless communication module, a clock circuit, a storage circuit, an interface circuit, and is integrated on the circuit board by an SMT surface mount process. It has the functions of collecting analog quantity, digital quantity, command control output, data storage, data transmission, display and keyboard setting, which can complete various operations required by the oil well; the main circuit board is equipped with microprocessor, RS232/485 interface circuit, Wireless data transceiver module, keyboard display circuit, data storage circuit, clock circuit, USB interface circuit and power supply circuit.

2.System functions

Data collection and communication are the basic functions of oil fields, including wells, pumping wells, electric submersible pump wells, screw pump wells, water injection wells, water distribution rooms, water injection stations, oil and water gathering pipeline networks, booster stations, and oil transfer stations. Data from oil (gas) wells and field stations at production sites such as gathering stations and tank farms are collected into the database, and remote control of the site can be realized through communication functions.

3.Production data storage:

Provide production data storage functions for oil fields, and build the basic data center on which the upper-layer applications of smart oil fields depend. The production data archive storage does not depend on the third-party relational database to jointly build the data center on which the upper-layer application depends.

Production real-time monitoring

Field production data such as oil wells, water supply systems, booster stations, metering stations, joint stations, and pipe networks are collected into the platform real-time database through data collection technology. Enables operations managers to view on-site production status anytime, anywhere.

Production alarm

Through real-time monitoring of production and operation status of oil wells, gas wells, water injection wells, gathering, transportation, gas distribution stations, dewatering stations, boosting stations, valve rooms, treatment plants, and pipe network equipment, the system platform can pass any abnormal situation. The alarm mode informs the relevant operation management personnel. The system alarm mode is mainly divided into: sound and light, image, screen icon flashing and video surveillance linkage.

Power metering

The real-time database and the relational database jointly complete the dynamometer data monitoring, equipment condition analysis and dynamometer display, calculate the production of the oil well, and judge the working condition of the pumping unit. The power map comparison and analysis function can be used to query and analyze the historical power maps in any time period, for dispatchers to analyze the working conditions of all oil wells and the oil meter production, and effectively embed them with other production monitoring and management portals. And integration to form a unified digital scheduling and management platform.

4.The topology is as follows:

5. Program summary

Through systematic integration processing, the system not only supervises and monitors production safety, but also protects the safety of workers' lives and property, indicating that oilfield safety production monitoring is essential. Caimao wireless devices are constantly striving to increase the pace of research and development on wireless communication modules to contribute to the wireless industry.