Solution Based on Industrial Grade 4G Router in Remote Monitoring of Heat Exchange Station

Time:2018-11-23 Source:In recent years, the scale of urban central heating has continued to expand. Centralized heating is an energy-saving and environmental protection measure promoted by the state. The heat exchange station is an extremely important link connecting the heating station and the user. Its work safety and reliability directly affect the safety of the boiler and the quality of heating. At present, many areas of the heat exchange station are manually monitored, which wastes manpower on the one hand; on the other hand, it is difficult for operators to find out when there is a hidden danger, which is easy to cause equipment accidents. At the same time, each heat exchange station operates independently, especially for centralized heating equipment, with a large dispersion range, high real-time requirements, and avoidance of interference. To continuously monitor the surrounding environment of the heat exchange station in real time, relying on the traditional method.In the past,it is difficult to meet the requirements.

The remote monitoring system of the heat exchange station of 4G industrial router consists of four parts: monitoring center, wireless transmission terminal, on-site monitoring equipment, on-site measuring instrument and measuring and controlling equipment.

Second, system composition and main functions

1. It consists of four parts: monitoring center, wireless transmission terminal, on-site monitoring equipment, on-site measuring instrument and measuring and controlling equipment.

2. Monitoring center: namely the central server, PC monitoring software, etc. 3. Wireless transmission terminal: 4G/3G industrial wireless router, based on wireless communication networ(Unicom/Mobile/Telecommunications). 4. Field monitoring equipment: monitoring terminal On-site measuring instruments and metering equipment: heat meters (or flow meters, pressure sensors, temperature sensors, etc.), valves (or pump starters), etc.

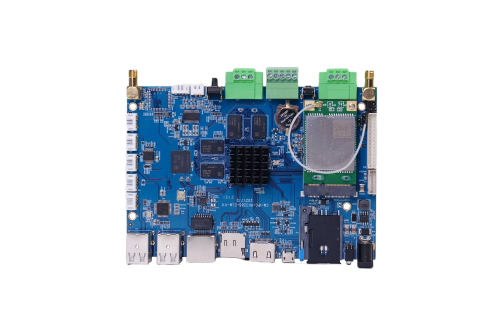

Third, the system core products

The 4G industrial router CM520 series is connected to the equipment in the monitoring terminal, interpolating the SIM data card, and the monitoring terminal and the data management center form a network communication through the 4G/3G network. CM520 series transmits the live video image, equipment operation and maintenance status of the heat exchange station to the monitoring center in real time. The monitoring center can collect, analyze and optimize the real-time data obtained, and realize the remote monitoring and monitoring of the data management center.

Fourth, the system realizes customer value

At the same time, the system will transmit information such as equipment operation and maintenance status to the monitoring center and various production management departments in real time, providing accurate and timely first-hand information for production command and dispatch, reducing the required on-site duties and maintenance personnel, and maximizing the protection. The heat exchange station is in normal operation.