CAIMORE RTU Enter the Digital Smart Factory

Time:2021-04-24 Source:Since the German government officially announced at the Hannover Messe in 2013, the concept of "Industry 4.0" has swept the world and is considered to be the fourth industrial revolution with cyber-physical system (CPS) technology as the core.

As the biggest theme of Industry 4.0, smart factories can be described as running through the entire process of industrial upgrading. The smart factory mainly studies the realization of intelligent production systems and processes and networked distributed production facilities.

The main features of the smart factory include:

1. Use the Internet of Things technology to realize efficient information interconnection between equipment, and the digital factory is upgraded to the "Internet of Things Factory". The operator can obtain the dynamic production data of production equipment, materials, and finished lights to meet the 24-hour monitoring needs of the factory;

2. Realize data mining and analysis based on a huge database, so that the factory has self-learning ability, and on this basis, complete tasks such as optimization of energy consumption and automatic judgment of production decision-making;

3. Introduce highly intelligent automated production lines based on computer numerical control machine tools, robots, etc., to meet the needs of customized and flexible production, effectively shorten the product production cycle, and greatly reduce product costs at the same time;

4. Supporting intelligent logistics warehousing system, through automatic three-dimensional warehouse, automatic conveying and sorting system, intelligent warehousing management system, etc., realize the real-time data entry of each link in the warehouse management process and the efficiency of the management of goods in and out of the warehouse;

5. The factory is equipped with electronic billboards to display the real-time dynamics of production. At the same time, operators can remotely participate in the correction or command of the production process.

Production operations | Additive manufacturing can quickly produce prototypes or small batches of parts; Advanced planning and scheduling based on real-time production and inventory data to minimize waste and shorten cycle times; Cognitive robots and autonomous robots can effectively carry out routine tasks, save costs as much as possible, and improve accuracy; |

Warehouse operation | Assist staff in selection and placement tasks; Autonomous robots can carry out warehouse management work; |

Inventory tracking | The sensor can track the real-time movement and location of the first-level high-value molds of raw materials, semi-finished products and finished products; Analysis can optimize existing inventory and automatically remind to replenish inventory; |

Quality | Use optical analysis methods to develop mid-term quality issues; Set up real-time monitoring to predict potential quality problems; |

Maintenance | Assist maintenance personnel to carry out equipment maintenance work; Sensors on the device facilitate predictive and cognitive maintenance analysis; |

Environment, health and safety | Sensors can warn when dangerous equipment is close to workers; Sensors on staff can detect environmental conditions and confirm whether it is operating normally or whether there are other potential threats; |

Industrial communication wireless

The wirelessization of industrial communications is currently a hotly discussed issue for smart factories. According to expert analysis, by 2013, the application of wireless communication systems in global factory automation will increase by about 40% every year. With the increasing popularity of wireless technology, a series of software and hardware technologies help increase communication functions in products. The communication standards supported by these technologies include Bluetooth, Wi-Fi, GPS, LTE and WiMax.

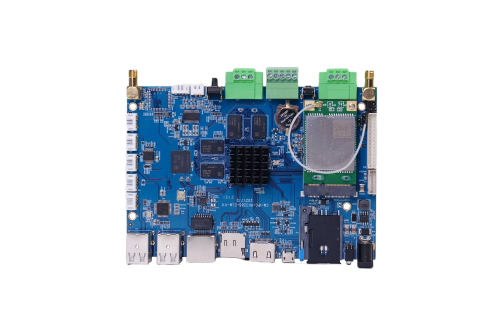

CaiMore RTU is produced by independent research and development and has the functions of data collection, remote control and wireless communication. It integrates analog signals acquisition, digital input, digital output, count, wireless data communication, and it can directly access all kinds of analog signals, level signal, dry contact and pulse signal output by sensor, standard transducer signal, instrument etc., which is the best choice of implementing wireless monitoring.

CM550 series adopts high-performance industrial 32-bit communication processor and industrial wireless module. It is embedded with real-time operating system to provide on-line maintain technology for software support platform device. Meanwhile, it also provide RS232 and RS485 interface to achieve the acquisition of analog signal and digital signal.

Interface | |||

Switch/Counter Input | Switch | 8 ch. | DIG & DI1 ~ DI8 |

Counter | 6 ch. | DI3 ~ DI8 | |

Analog Input | 8 ch. | AG & A1 ~ A8 | |

PWM Output | 2 ch. | PWMG & PWM1 ~ PWM2 | |

Relay Output | 4 ch. | K1 ~ K4(+/-) | |

Optocoupler/Digital Output | 4 ch. | COM & DO1 ~ DO4 | |

RS232(Debug) | 1 ch. | D/RX & D/TX & GND | |

RS232(Communicating) | 1 ch. | U/RX & U/TX & GND | |

RS485(Communicating) | 1 ch. | A & B | |

CAMORE-RTU-CM550

CAIMORE Qualification and testing

1, wireless communication online maintain patent technology

2, Moore Laboratory’s high and low temperature test report

3, Product Quality Inspection Detection of Fujian Institute

4, copyrights certificate

5, EMC test report

6, the state compulsory 3C certification

CAIMORE TOP 5 manufacturer of Industrial Network Comms products since 2003.For your quick reference,there are five production lines in Caimore.1- Vehicle WIFI Advertising Router,CM5202- Industrial wireless Router,CM5203- Industrial PC,CM5804- NVR ,CM5305- DTU/IP Modem/CM5106- RTU/IO Gateway/IO Modem,CM550

Bella Liu/Sales Engineer

M: +86 177 0008 2379 (Wechat/WhatsApp)

Email: oversea@caimore.com